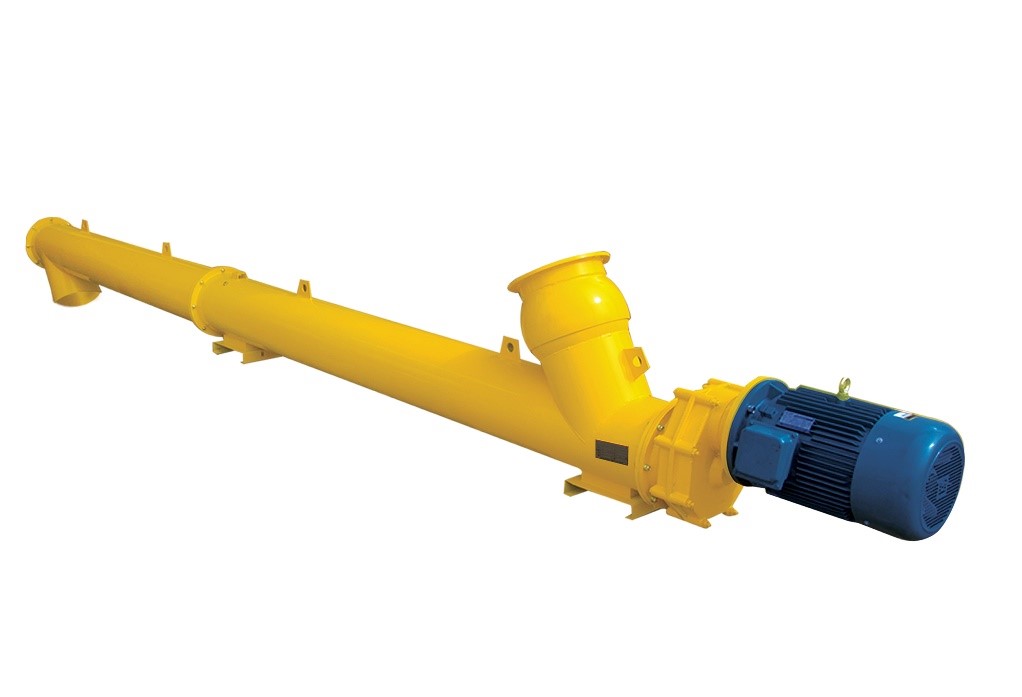

Screw Conveyor for Cement

Product Description

The domestic most advanced five-axis CNC intersecting line cutting machine is used for discharging outer tube. The outer tube, inner tube and feed pipe are welded by using CNC automatic welder so as to ensure the coaxiality of outer tube and inner tube as well as the welding quality.

The hard teeth surface gear reducer is featured by heavy duty design, high strength, large torque, low noise and long service life.

The feed inlet uses universal ball joint, and it can be easily installed and adjusted. The common diameter is 168, 219, 273, 323. It has a large inventory and a short production cycle, and can be customized according to customer requirements.

The one-step forming vane is featured by double pitch design and no blockage. The Siemens motor is used. Standard assembly and convenient transportation.

The main features

Adopt high-quality steel pipe with good integral rigidity.

Double pitches or three pitches design, which decrease the compression degree of material when being transported,and avoid blocking. Adopt high-quality reducer with heavy-duty design, large torque and low noise.

Adopt optional universal ball joint, which facilitates installation, adjustment and steering.Inlet equipped with high-quality middle-hoisting bearing and tail bearing.

Sufficient spare parts with complete specification.

Large stock for common diameter of 168, 219, 273, 323 and 407, and dimension & angle can be customized according to your requirement.

Assembled by standard parts and components, which makes it convenient for transportation.

Adopt Siemens motor.

Advantages:

We have suceessfully developed and put into batch production for Non-greasy lubricate screw conveyor.

1.Adopt non-greasy bearing ,reliable in using and we guarantee 1.5 years.

2.Avoid trouble of oil injecting and save grease.

3.Simple in structure and easy for maintenance.

Details

Explanation:

1.The number’s meaning in table: reducer model-transmission ratio-diameter of charging shaft-motor power.

2.Adopt upper limit power when the effective length of screw conveyor than or equal to L+0.5 meter,otherwise adopt lower limit power.